COMIA C10

The quietest cab in its size class on the market. High-power straw chopper and cutting table side tilt as standard. These are just a few of the benefits the C10 offers.

Watch video

Watch video

The C10 is equipped with one threshing cylinder and is the “first” harvester of the larger COMIA series. The efficient and steadily rotating HD threshing cylinder, with eight rasp bars, has been equipped with metal bars that are covered on the back. This ensures that dirt won’t get caught behind the rasp bar, and it simultaneously increases the efficiency of the flywheel effect. Large separation areas on the sieves and straw walkers make this model extremely efficient. The AVARA cab is excellently equipped and includes e.g., direct height control (DHC) for the header and electrically adjustable mirrors. Efficiency is further increased by the large grain tank, fast unloading speed and the unloading pipe with a high unloading height.

Cab

AVARA - style and functionality

Eight work lights, modern LED headlights, and a wide windscreen. One of the factors considered during the design of the cab, was the driver’s clear visibility of the cutting header. The harvesters of the COMIA series have a multi-function drive handle, and the layout of the other controls has also been carefully designed. All threshing-related activities, such as the controls of the machinery and cutting header, are located in the armrest. The console also has 12V and USB connectors. You can easily control the modern COMVISION II touchscreen with one hand while harvesting. It is very easy to monitor threshing, when at the same time you can see e.g., the grain loss monitor, height of cutting header, speed, and warning lights. Any alarms can be seen on the COMVISION II screen as pop-up warnings, and the system also gives out an audible signal.

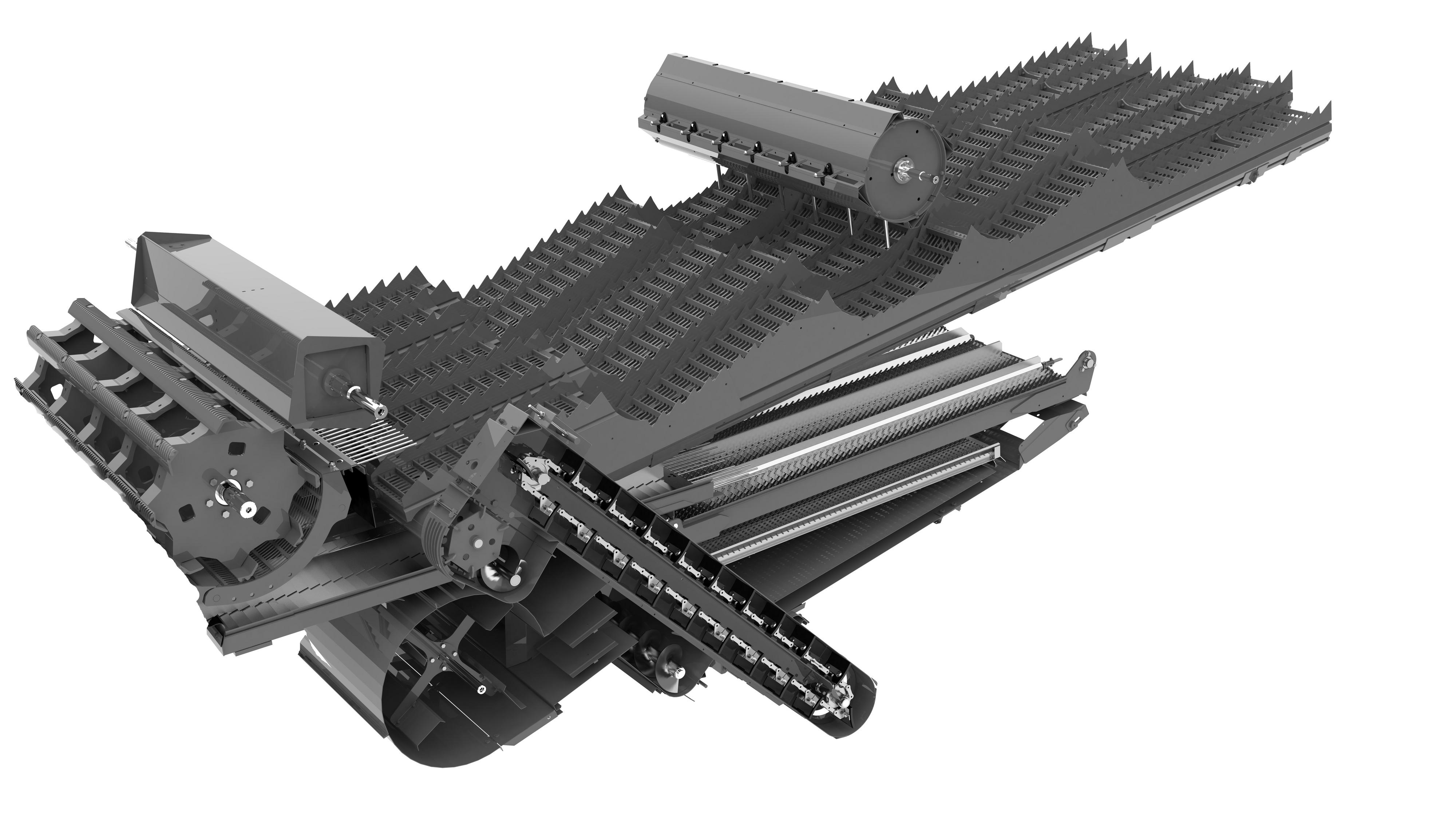

Cutting headers

Excellent cutting headers

Easy to connect, recognised for its geometrics, and fully hydraulic operations. The nylon/plastic tines of the pick-up reel, which have been found to be effective and the hydraulic header reverse put the finishing touches on this highly functional cutting table. Whether growth is high or low, COMIA’s cutting header, which has been developed over several years, can handle it. The optimal distance from the knife to the feeder auger ensures an uninterrupted feed to the combine's feeder elevator. Manual side tilt and direct height control (DHC) come as standard.

Threshing mechanism

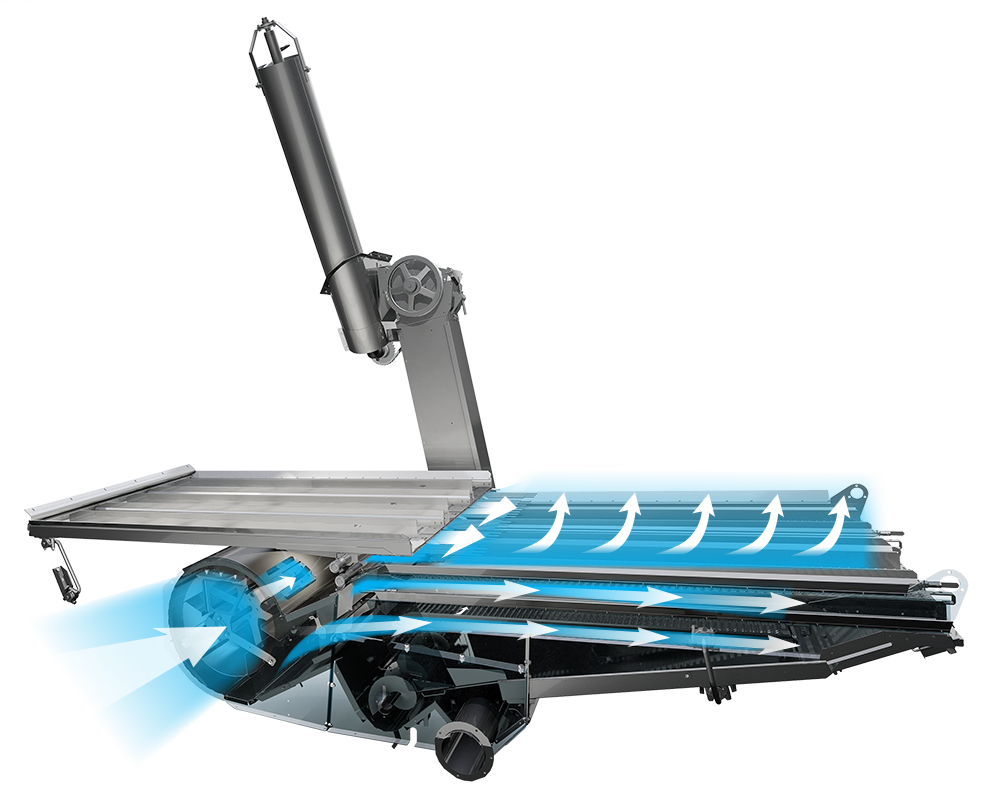

NEW Features on the threshing system, GEN3

The NEW GEN3 Comia chassis includes three updates compared to MY21. New cylinder variator pullies, with load feeling tensioning off the belt. 100% more capability to transmit power and service free since you don’t need tension the belt during the season. An improved six blade fan, with better airstream supply to the sieve box area. Air is supplied with a stronger force and more even over the whole sieve area. This has been made with improved geometry of the sieve area and more movement of the sieve box. To match the capacity increase, a NEW robust and wide grain elevator ensures the transport of the material all the way to the grain tank. The elevator can move 80tn/hr.

Threshing mechanism

Efficient threshing mechanism and versatile settings

The 134 cm wide threshing mechanism with its eight-rasp-bar HD threshing cylinder ensures good threshing in this combine harvester equipped with a single threshing cylinder. The cylinder is truly HD, as the back of its counter bar is covered with a steel plate. This way dirt and dust won’t get stuck and the cylinder always stays balanced.The six straw walkers and a large straw walker surface ensure good separation. The RV2 lamella upper sieve efficiently removes chaff and the RV3 lower lamella sieve separates clean grain into the tank. The returns are threshed with the elevator on the left side of the machine and with the after thresher at the end of it. The returns are returned to the centre of the grain pan with a screw and are distributed evenly on the entire grain pan. This way, the returns do not load the threshing cylinder and instead travel their own route.

Transmission

Power and durability

Every combine harvester of the COMIA-series has a strong three-gear gearbox. The gearbox has a hydraulic clutch assist, which makes shifting easy and handy. In order to activate the clutch assist, you simply press a button on the gear stick. The gearbox is powered by a strong hydraulic motor, which can be controlled continuously from the cab using the drive handle. A strong front axle equipped with final drives and disc brakes, allowing for the use of wide tires. Optionally, the COMIA can be equipped with extra wide tires. You can check from the specifications, which tiress go with your COMIA. Hydraulic four-wheel drive, which helps driving in tough conditions, is available as an optional extra.

Cleaning

The undisputed leader on the market with regards to cleanability

Thanks to their technical solutions, the SAMPO ROSENLEW combine harvesters have always been easy to clean. For example, the grain pan sections can be extracted and the straw walker bottoms can be removed. Although the same features may be included in other makes, SAMPO has implemented them so that you do not have to carry out cleaning in your service area. Instead, you can clean them on the field and have more uptime.

Grain tank

The bigger the tank, the greater the efficiency

The COMIA C10 has been equipped with a 6,000 litre grain tank. When threshing, the lid of the grain tank must be lifted, but this is easily done electrically from the cab. The unloading speed is a whopping 100 l/s and the unloading height is 4.4 metres. The length of the unloading pipe is also sufficient, even with a wider cutting headers. The long unloading pipe can easily be swung by pressing a button on the drive handle. Unloading is also started from the drive handle. A large grain tank window allows easy monitoring of the filling of the tank. The tank is illuminated with a powerful LED light. This way you can monitor the grain quality also at night. The filling alarm of the tank is connected to the COMVISION II screen, and it lets you know when the time comes to empty it.