Localization

LOCALIZATION POSSIBILITIES

Sampo Rosenlew Ltd can provide an affordable and exceptional way to purchase and sell always up to date combine harvesters. We are in a continuous search for long term partnerships with companies who have an understanding for mutual benefits of a local manufacturing.

SUB-ASSEMBLED COMBINES

In addition to our ready-made products, we can provide sub-assembled combines. The distinctive advantages of module delivery enables optimized freight costs in containers and fast shipping. Every combine we provide can be produced according to our latest innovations and enhancements.

WORK WITH EXPERIENCED PARTNER

A local assembly project is always a long term partnership, where both parties are committed to a common project for several years.

BENEFIT FROM LOCALIZATION

In co-operation with Sampo Rosenlew a local manufacturer can start its own production operations and as the know-how grows, they can start their own after sales business.

Local manufacturing enables our partner to use local suppliers, labor and finances.

ONE-OF-A-KIND DEAL

Additional to any other combine harvester manufacturer, we don’t only localize assembly, but also localize part manufacturing, welding, machining and even supply management.

Sampo Rosenlew is the only combine harvester manufacturer offering this kind of co-operation.

CUSTOMIZED PRODUCT FOR YOUR NEEDS

While our combine harvesters were originally designed for the challenging harvesting conditions occurring in northern latitudes, they are equally well suited for use in hot and dry climates.

Sampo Rosenlew combine harvesters are used to harvest wheat as well as rice or any other crop in different conditions all around the world.

DEVELOP LOCAL AGRICULTURE

Food security

– Food price is increasing significantly

– Secure your local food production

Develop local agriculture and food production

– Increase productivity

– Decrease grain losses

– Develop new agricultural business models

DEVELOP LOCAL INDUSTRY

– Increase level of industrial know-how and machinery

– Develop local agricultural machinery manufacturing

– Employ local people

– Save freight costs

– Reduce costs by using local suppliers

– Build up a local financing system targeted for local products

– Improve after-sales services

FULL SUPPORT TROUGH THE PROCESS AND FURTHER

We provide pre-assembled modules, know-how and education as well as a comprehensive documentation. On site supervision is also available for our partners. Assembling combine from modules on site will help our partner to lower the total costs.

WORK WITH EXPERIENCED PARTNER

Sampo Rosenlew Ltd

– Located in Pori, Finland

– Metal production since 1858

– Distribution network in 50 countries

– Turnover 2022 52 million euro

– 250 employees

– 90% goes to export

The company’s main products are combine harvesters and forest harvesters. Combine harvesters account for nearly 60% of net sales.

Sampo Rosenlew Ltd was set up in 1991 through a management buy-out. Business operations were first started on the present premises in 1853 by Oy W. Rosenlew Ab, a family business. Business started by shipping timber, and then gradually diversified into agricultural machinery. Combine harvester was launched in 1957. It gradually became the most successful product in the product range.

The home of the corporation is located in Pori, where combine harvesters and forest harvesters are manufactured. Sampo Rosenlew is owned today by the Indian multi-industrial company Mahindra&Mahindra.

Sampo Rosenlew is currently selling its machines to over 50 countries and exports appr. 90% of its products. Main markets are in Europe and CIS countries.

Sampo-Rosenlew’s recent success is heavily based on the idea of a local assembly. In practise it means developing local agriculture and food production. It also employs local people. At the same time it reduces freight costs and improves after sales services. Costs are also reduced by using local suppliers.

FULL SUPPORT TROUGH THE PROCESS AND FURTHER

MODULES & KNOW-HOW

We provide pre-assembled modules, know-how and education as well as a comprehensive documentation. On site supervision is also available for our partners. Assembling combine from modules on site will help our partner to lower the total costs.

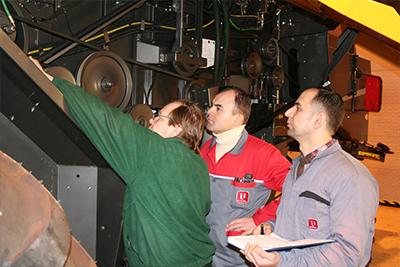

PRODUCTION ENGINEERING

We can provide know-how to our partner with the support of our specialists, who are available when starting the assembly project in a local factory. One of the most important parts of this support is quality. First products or new models will be audited by our quality specialists. All quality requirements are the same as for combines coming from our own factory in Finland.

PRODUCTION ADVICE & TRAINING

Every project has its own detailed training programs. Programs are based on a local specification, localizations, technology level and local know-how. Each new localized component has its own training first at our factory and then in the local factory. The key issue is training by doing. Every new localized component is only released after the certain quality steps.

TRAINING & EDUCATION

We will also organize field trainings for local service people. Service people will learn to work with final customers in field conditions. This training also includes how to train customers to use the full capacity of his new Sampo Rosenlew combine harvester. Our field engineers will visit frequently in fields in order to train but also to increase the knowledge of chancing varieties and conditions.

EDUCATING LOCAL FARMERS

We will bring a new level of agricultural technology to our partner country. This means that also local farmers should be trained to new machinery and technical aspects. Only by proper training to local farmers we can ensure full benefit of new machinery. This will increase the yields, decrease grain losses, increase uptime and maximize the harvesting capacity.

TECHNICAL SUPPORT

Technical support will be available in all major languages directly from our factory. There are specialists for different kinds of support: manufacturing engineering, research and design, service, spare parts, sales… In every project there is a project team. People in the local manufacturing site know by name their own support personnel and can contact them directly.