Verrato V5

The Verrato- series V5 continues that legacy, the SR 2000 -series started. These series have served farmers´ needs indefatigably over decades.

Watch video

Watch video

The Verrato- series V5 continues that legacy, the SR 2000 -series started. These series have served farmers´ needs indefatigably over decades. The range has been sold throughout the world to thresh the most exotic species of plants. The feedback received from round the world has helped us develop our combines more versatile and reliable than ever. A host of appreciated properties are combined in this combine harvester – a wide cutting table and threshing unit, a good selection of different engines and a large grain tank.

Cab

Practical and basic

The V5 is equipped with a SR –standard cab. If the combine is equipped with mechanical transmission, there are four hydraulic levers independent of the model. On hydrostatic transmission models, you control the combine with a multi-purpose lever. The lever includes the header adjustments, lifting the header and reel up and down.

Cutting table

Tested technology

There are several table widths ranging from 3.1 to 5.1 metres. The table width can be chosen depending on threshing speed or field sizes. Dealers can be consulted about the right width to suit your particular needs. A table auger with a large diameter feeds the grain efficiently into the combine. The work is facilitated by robust feed fingers throughout the whole width of the table on tables 3.9 metres wide and wider. Reel height is adjusted hydraulically, and reel speed electrically. The fore/aft adjustments is mechanically.

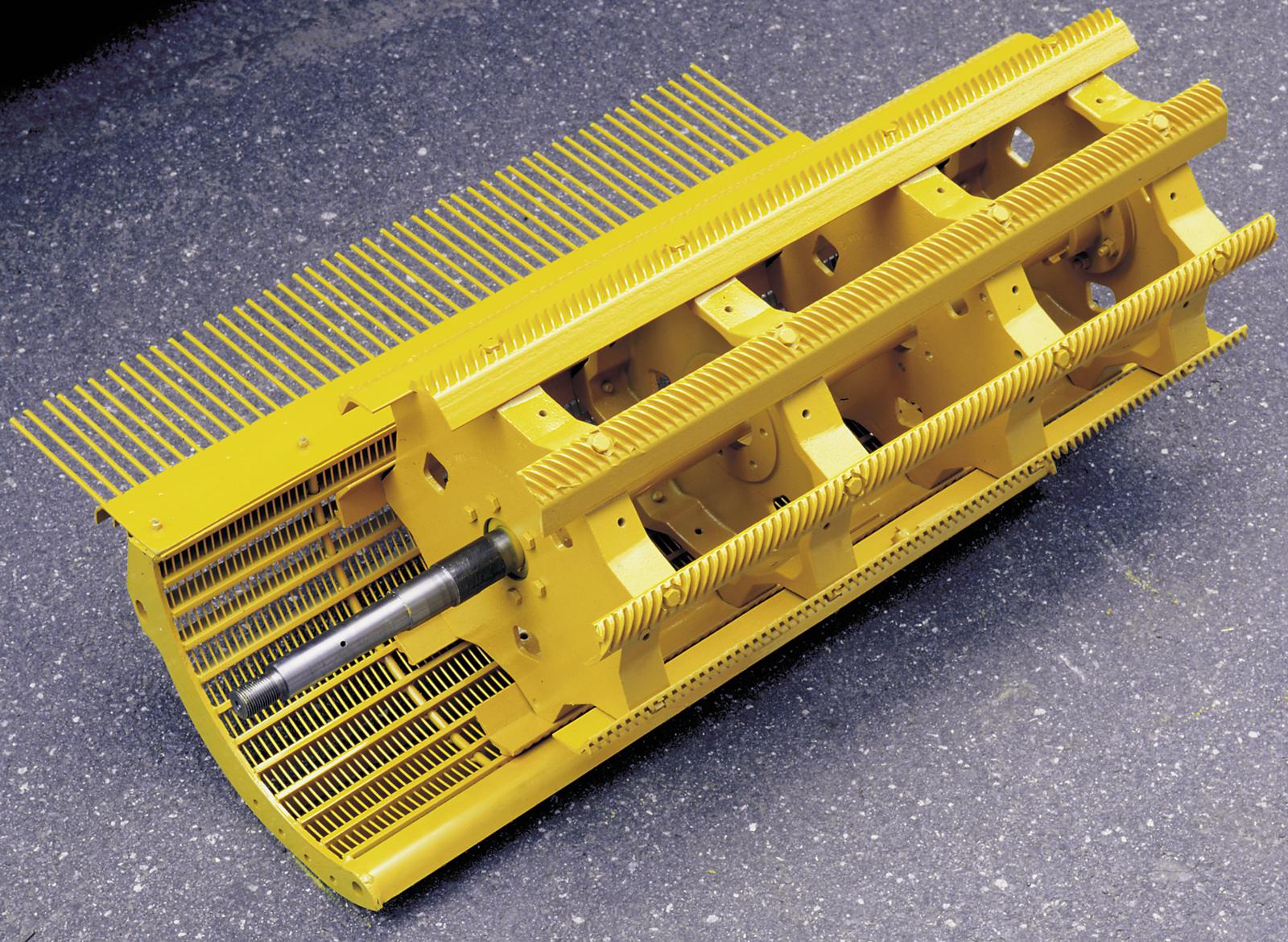

Threshing mechanism

Efficient threshing mechanism

The 50 cm diameter and 111 cm wide threshing cylinder separates the grain easily and carefully. The V5's concave is specially designed for grain harvesting. The concave wires are designed thin for accurate threshing. The largest shaker shoe area in its size class provides clean grain in all conditions. The total shaker shoe area is 3.40 square metres. The chaffer is of the modern lamella sieve type. On the RV2 lamella sieve, every other lamella is bent down to efficiently prevent straw fragments from entering the grain tank. The grain sieve is of the hole sieve type. The Verrato V5 has five straw walkers, with four steps.

Special crops

Agile platform for any crops

For harvesting special crops you need a different header fitting. For corn a 4 row corn header can be fitted to the V5, if needed. Also sunflower attachment are available or a sunflower header. Rice equipment are also available.

Grain tank

Different sizes available

The combine can be equipped with different grain tank options to suit your needs. The height of the cover determines the tank capacity. Grain tank capacities are from 3,300 to 4,200 liters. The bottom of the grain tank is of a W shape type on every model. This design with the filling auger located in the centre has proved extremely efficient in an even distribution of the grain in the tank. The unloading pipe is sufficiently long. The unloading height is standard 3.3 meters or you can choose as an option 3.4 m or even 4 m high.

Transmission and engine

Power and efficiency

Verrato V5 can be equipped with different engines. Depending on your countries emission controls the combine can be equipped with Tier0 or Tier3 engines. The power rate is from 150 hp up to 185 hp, 6 cylinder engines. Efficient suction located on the intake air mesh ensures that the large cooling cells are continuously supplied with fresh air. A rotating suction air screen is standard. A belt driven blowing impeller located outside the cooler supplies enough cooling air. The combine can be equipped with mechanical or hydrostatic transmission. If the combine is equipped with hydrostatic transmission a 4-wd can be fitted as well. Different tire options are available also, depending of your harvesting conditions.

Cleaning

The undisputed leader on the market regarding the cleanability

Thanks for the technical solutions, the Sampo-Rosenlew combine harvesters have always been easy to clean. For example, the grain pan can be extracted and the straw walker bottoms can be removed. Although the same features may be included in other makes, Sampo has implemented them so that you do not have to carry out cleaning in your . Instead, you can clean them on the field and save time. In the Verrato model, all of the grain tank augers can also be removed. A good basic combine harvester for threshing even large areas. A compact combine harvester built on the Comia series frame.