HR46x

The HR46x is the most reliable, environmentally-friendly and economical harvester for first thinning of young forests all around the world.

Katso video

Katso video

Tipisks svars

8000-9 500 kg

Celtņa sasniedzamība

7,1 m

Celtņa pacelšanas griezes moments

55 kNm

Dzinējs

140 kW

Frame

Intelligent frame structure, agile machine

The work place of a thinning harvester is a young forest. It grows fairly densely in order to maximise timber production. Good quality thinning requires that the machine is fairly small and can turn in a small space. The machine also has to be light. This is exactly what the HR46x is. The high-quality frame is light but sturdy. Its unique agility is ensured by the narrowness of the machine as well as the large 50 degree turning angle of the centre joint. The outer radius of the turning circle is 402 centimetres. Tyre width can be selected between 540 and 710 millimetres.

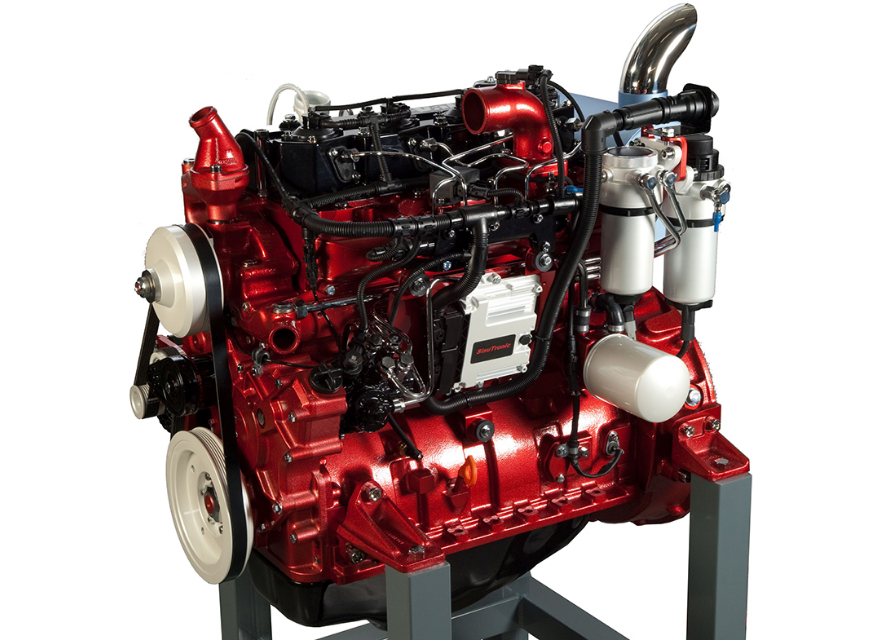

Transmission

Lots of power in a small package

The power transmission is fully hydrostatic. The system contains no easily damaged, mechanical axles or wheelwork. The variable speed radial piston motors change gears electrically. The torque of the drive motors is high right from the start and there is enough power to handle any situation. No tracks are left in the thinned forest and the ground is not damaged by turning either as there is no bogie. SAMPO ROSENLEW uses engines manufactured by AGCO POWER with several decades of experience in Linnavuori, Finland. The power plant of the HR46x is the TIER 5 common rail and SCR technology-equipped Power 49 LFTN diesel engine. The low fuel consumption of the low-emission engine, coupled with extended service intervals, ensure low operating costs. It has a maximum power of 140 kW and torque is highest exactly in the RPM range that is used the most in operation. The tried and tested motors are silent.

Cab

Productivity is done in the cab

The cab of the SAMPO ROSENLEW harvesters has always been located on a different frame than the motor, which is why the working environment is always pleasant and quiet. Working is efficient in the spacious and quiet cab designed by Sampo-Rosenlew Ltd. Visibility is excellent also to the tops of the trees, which is the requirement for choosing the right trees for thinning. The cab design, which fulfils all official standards, makes moving in a dense forest easy and does not harm the remaining trees. Many details that make work easier and more comfortable can be found in the cab.

Crane

Easy to use

The 7.1 metre reach and more than 55 kNm lifting torque of the HR46x’s crane ensure smooth work. The crane is also agile to use in a dense forest. The side tilt, which can also be switched to automatic, helps pick out just the right trees and makes working on a slope or in uneven terrain easier. The low structure of the crane adds to the latitudinal stability of the machine and improves visibility of the trunks, as does the vertical attachment, which allows the base of the crane to be located as close to the driver as possible.

Harvesting head

Always right for the job

We only use harvesting heads from well-known manufacturers. The main brands are Kesla and Keto. For thinning, the harvesting head should be small and designed so that it is easy to move to the tree to be harvested in the dense forest without harming the remaining trees. The harvesting head and accessories are selected based on the intended use. For example, there are specific equipment or applications for the standard harvesting head designed for producing energy timber.

Measuring computer

Precisely calculated

The measuring computer in charge of the measuring of the timber and the control of the harvesting head. Because the needs of clients vary, the Technion computer we use can be equipped with software of different levels. If there is a need for functions that require PC-level performance, a computer is connected alongside the actual measuring device. This way, a possible malfunction of the PC won’t hinder the use of the machine. All necessary functions are available with the measuring device, such as: - Trunk cutting optimisation - Harvester head control, monitoring and fault diagnostics - Work time monitoring - Wireless transfer of production data